即使在正常情况下,亚马逊的全球分销网络也是地球上最复杂的物流系统之一。系统当中无数的地址、人名,还有各种技术,仿佛是在共跳一支极其复杂的舞蹈,结果是将数百万个快递送到正确的地方。

当新冠疫情来袭,常态顿成往事。然而在疫情封锁期,全美几乎所有人仍要工作、学习,而且只能在家购物。亚马逊订单突然激增,其中也包括大量囤积食品和卫生纸等,这导致运营网络一片混乱。而且,由于物流网络中多数员工没法在家工作(毕竟不可能在客厅里送快递或开叉车),突然之间亚马逊还要为数十万员工的安全负责,其中很多人面临感染新型冠状病毒的风险。

两大挑战都直接落在到亚马逊工作还不满一年的高管身上。艾丽西亚•博勒•戴维斯于2019年4月加入亚马逊,担任全球物流副总裁。从职位就能看出,博勒•戴维斯掌管着庞大的基础设施,目标是帮助消费者在亚马逊轻松购物。“物流业务是亚马逊零售业务的心脏,”追踪亚马逊的Baird Equity Research分析师科林•塞巴斯蒂安表示。由此博勒•戴维斯也变成行业领跑者,她管理着亚马逊全球数百座仓库,监督员工、物流和流程,以及理货机器人等多项技术。客户服务也囊括在内,疫情之中亚马逊的客户需要的服务比以往更多。

虽然博勒•戴维斯加入亚马逊不久,但她并不是新手。她在来到西雅图加入亚马逊之前曾于通用汽车工作25年且业绩顶尖,曾负责管理工厂,与工会谈判,监督开发热门新车型,还帮助公司挺过了艰难的召回事件。“在亚马逊,人们行动非常积极,”博勒•戴维斯说。“一旦发现问题,就要迅速找到解决方案并尝试不同的想法。如果找到了可行方案,就尽快分享推广。”疫情期间挑战不断升级时,博勒•戴维斯在通用汽车期间练就的强大多样的技能让她临危不惧。

首先要解决的问题是供应链不堪重负。疫情期间,亚马逊优先配送卫生用品、防护装备和其他疫情相关需求,非必需品发货则可能推迟数周。与此同时,庞大的新增需求量造成了瓶颈,要求配送渠道迅速拓展。博勒•戴维斯带动公司加速扩张,过去几年里,亚马逊在全球各地的物流中心面积每年增加约15%,仅2020年就将增长50%。过去6个月亚马逊雇佣的20万名员工中,大部分都是直接为新物流中心配备,而能如此迅速招聘20万人本身就很惊人。

更艰巨的任务则是保护员工安全。在博勒•戴维斯看来,保障安全意味着在仓库中增加社交距离规则且测量体温(刚开始用手持设备,后来用体温监测摄像头),增加新冠病毒筛查,并全面检查150个工作流程。就连指导员工配货的亚马逊物流算法也要改写,以实现人员密集度降低。口罩和消毒用品等关键产品持续短缺,亚马逊不得不寻找新供应商。“这可能是我做过最具挑战性的事,”博勒•戴维斯说。

亚马逊在安全方面并不完美,尤其是疫情初期。仓库一些员工抱怨说没机会享受带薪病假。纽约员工还发起了一场GoFundMe运动,支持同事无薪休假。如果有员工检测出阳性,一些仓库就得关闭。不过,博勒•戴维斯和其他高管充分了解疫情范围后,亚马逊开始疯狂投入——仅二季度就投入40亿美元改进工作流程并升级安全措施。

320,000,000

截至2020年10月,亚马逊全球物流设施的占地总面积达320000000平方英尺(数据来源:供应链咨询公司MWPVL国际)

本月早些时候亚马逊报告称,140万一线员工中近2万人自3月初以来检测呈阳性,其中包括Whole Foods超市员工、临时工和季节性员工。尽管数字听起来很高,但感染率仅为1.4%。而且亚马逊表示,根据所在社区的感染率计算,阳性病例总数比预期的少42%。

亚马逊的大力投入也收获了很突出的财务回报。二季度公司营收较去年同期飙升40%,达到创纪录的889亿美元。背后推手主要是新一波电商浪潮,目前电商业务占总销售额的近60%。在混乱的二季度里,亚马逊利润翻了一番达到创纪录的52亿美元。其业务弹性也让投资者放心,股票市值推高至1.6万亿美元。

抗疫胜利很可能也推动博勒•戴维斯的职位水涨船高。今年8月,她升任亚马逊高管核心团队S-team(S代表“高级”)成员,直接向首席执行官兼创始人杰夫•贝佐斯提供建议的重量级人物。现年50岁的博勒•戴维斯是第一位黑人,也是公司成立以来第四位跻身核心团队的女性。分析师认为,明年5月全球消费业务首席执行官,也是长期以来贝索斯的左膀右臂杰夫•威尔克将退休,届时高层人事将出现调整,她可能有进一步升迁机会。

博勒•戴维斯在通用汽车已证明自己可以胜任高层(她曾担任首席执行官玛丽•博拉的高级副总裁五年),也擅长灵活处理问题,职业上照此路线晋升也非常合理。她帮助亚马逊解决了诸多与疫情并不直接相关的问题,包括混乱的劳资关系和竞争对手的挑战等,可能对亚马逊维持市场主导地位很重要。虽然亚马逊不允许现任同事谈论博勒•戴维斯,但采访通用汽车前同事后,还是能侧面了解她从事当前职务拥有的优势。

博勒•戴维斯在底特律长大。母亲是记账员,父亲先在福特工厂工作,30多岁时上大学,毕业后在IBM当销售。(父母离婚后,她跟母亲住在一起,但父母都很关心她的生活和教育。)她小时候生活拮据,还记得9岁或10岁时试着修理房间里的东西。从老旧烘干机后面取出玩具并不困难,拼接熔化的铁线则麻烦一点。她回忆说:“那会可没法上谷歌搜索该怎么做,我被电过好几次。”

高中期间,这个热爱弄清楚各种东西运作原理的孩子参加了通用汽车赞助的暑期工程课程,也由此激发出她更宏大的抱负。博勒•戴维斯从西北大学化学工程专业毕业后,1994年加入通用汽车,在庞大的底特律-哈姆特马克工厂从事制造工作。通用汽车前人力资源主管克里斯•泰勒回忆称,你很快就能发现“她没准有一天能晋升为高管”。2007年,她成为通用汽车第一位非裔女性工厂经理,负责管理德克萨斯州阿灵顿市制造凯迪拉克凯雷德的工厂。

她事业上的大突破则跟小型车有关。2010年,通用汽车聘请博勒•戴维斯监督新的超紧凑车型雪佛兰Sonic。她负责设计并制定生产计划。对这位年轻的经理来说,“要考虑各不相同又得密切配合的领域,方能推出伟大的产品,”她说。通用汽车前高管,现在巴西现代汽车工作的乔尔•索亚雷斯•多斯安霍斯回忆称,该项目需要与通用汽车在韩国的伙伴密切合作,而当时韩国是男性主导的文化。“艾丽西亚在不同文化和国家之间应对得当,”他回忆说。讨论时她充分尊重男性,但坚定推进自己的议程,而且经常得胜。

Sonic在2010年底巴黎车展上正式推出,各种配色非常鲜亮,还包括一款掀背版,销量迅速蹿升。后来Sonic还屡获小型车领域最佳质量和可靠性奖。今年,研究公司J.D.Power表示,在各车型中Sonic出现质量问题最少。然而为了向电动汽车转型,通用汽车很快将停产Sonic,但很长时间里该款车相当畅销。Sonic的成功也推动博勒•戴维斯2012年升任负责全球质量和美国客户体验的副总裁,向另一位迅速崛起的通用高管巴拉汇报工作,2014年巴拉出任首席执行官。

博勒•戴维斯全面负责质量期间,通用汽车的质量大幅改善。她表示,当时听取各级员工建议,寻找机会将一处工厂里的好方法在各处广泛应用。“如果经常跟高层交谈就会发现,说话时他们目光迷茫,然后继续说别的,”韦恩堡一家通用工厂的长期负责人乔纳森•琼斯回忆道,他曾与博勒•戴维斯多次会面。“她跟别人不一样,似乎很关心你说的话。”

她迅速反应的能力也曾帮助通用汽车应对危机。2014年初,通用汽车不得不召回近200万辆点火开关故障的车。客服电话量翻了一番,博勒•戴维斯迅速搭建了100名客服代表组成的特情小组,专门针对召回问题接受培训,随后成功将等待时间缩短到不到一分钟。

2016年,巴拉任命博勒•戴维斯接替退休传奇人物,从业37年的老将吉姆•德鲁卡,出任全球制造和劳资关系执行副总裁。该职位要负责监管31个国家的171家工厂,雇佣18万名工人。对博勒•戴维斯来说,回到制造业让她回忆起早期在通用汽车公司工作的时光,“我在工厂里经历了很多。基本上是在工厂里长大的,”她说,“绕了一圈回来,如今要负责全球制造业务,我感觉很谦卑。”

此次晋升也提升了她的公众形象,也让物流需求复杂程度堪比通用汽车的公司之一开始关注她。

杰夫•威尔克是毕业于普林斯顿大学的化学工程师,长期以来一直是杰夫•贝佐斯的得力助手,也是亚马逊庞大电商设备的设计师之一。几年前,通过一位共同的朋友牵线,威尔克认识了博勒•戴维斯,还一起吃了午饭。她回忆说,威尔克对公司庞大业务了解十分深入,让她印象深刻。他谈论起亚马逊如数家珍,就像她谈论通用汽车一样。

当时博尔•戴维斯除了在亚马逊购物之外,对公司本身了解不多。但她做了些研究之后,对亚马逊以客户为中心的文化相当认同。“这与我的价值观和我喜欢的工作方式产生了共鸣”,她说。威尔克对她同样印象深刻,后来发出了工作邀请。(“我了解也热爱汽车行业,但为何不去别的行业试试呢?”博勒•戴维斯现在说。)今年夏天威尔克发给员工宣布博勒•戴维斯升任核心团队的邮件中写道:“我们很快就达成了一致。她的领导经验、对技术的敏锐,尤其是热爱为一线工人奉献的精神让我深受触动。”

如今三项优势都在接受考验。疫情来袭之前,亚马逊就曾打算在美国更大范围内提供更多品类的商品一日达服务,有时因配送量增大而难以提速。分析师一致认为,如果要实现这一目标,仓库网络要更大也更高效,还要在靠近客服的地方设置更多配送点。截至2019年底,亚马逊在全球有约175个物流中心。“我们还要增加很多,”博勒•戴维斯告诉《财富》杂志。“可以说,我们很可能要建立250到300个中心,至少涉足16个国家。”

“我认为,随着亚马逊将更多送货和配送纳入自营范围,博勒•戴维斯的重要性只会进一步提升,”Baird分析师塞巴斯蒂安表示。

由于零售业务和盈利的云服务业务都在挣得大量现金,亚马逊的基础设施建设热潮并没有让投资者感到不安。今年亚马逊股价上涨了80%以上。随着谷歌、微软和其他竞争对手削减亚马逊在云计算领域的领先地位,未来其现金流可能会减弱。至少从理论上讲,反垄断威胁可能影响利润。但目前来看,博勒•戴维斯团队有足够资金满足客户的需要,相当令人羡慕。

100,000

亚马逊预计2020年最后三个月在美国和加拿大招聘新员工的人数

如何将员工安置在新仓库里可能更为棘手。而且接下来是传统上亚马逊业务最繁忙的假日购物季。最近博勒•戴维斯宣布,到今年年底公司在美国和加拿大还要再雇佣10万名员工。(不能全交给人类员工:随着博勒•戴维斯推出更多新物流中心,装配更多亚马逊新款理货机器人也很重要。)

迅速招聘优秀员工绝非易事,围绕亚马逊工作环境的争议也增加了难度。一些现任和前任员工称,除了对病假工资福利的投诉,亚马逊还因薪酬和工作流程受到批评,按照相关流程,算法强行规定员工活动,休息时间也受到严格监控。美国工人兄弟会和其他工会都试过将亚马逊员工组织起来,但迄今为止收效甚微。

博勒•戴维斯从事汽车行业期间,以跟普通员工关系良好闻名,如果她在亚马逊能坚持风格,对公司必定大有裨益。“在通用汽车,小时工在创意、改进和工作方式等方面做出了很大贡献,”她说, “有一点我肯定不会忘,那就是对沟通的期待。”

她非常了解身为某一空间里唯一的女性或者唯一的黑人是什么感觉,所以也希望帮助更多像她一样的人发展。“孤立无援可能很难。不管会不会成为肩头的负担,这都是现实,”她说。她提携了一些后辈,也在亚马逊员工亲和力小组会议上发言。“我觉得开端还不错,”她说。

她努力建立凝聚力的过程中,至少有一位热情员工的加入可以归功于她。韦恩堡工厂负责人乔纳森•琼斯最近决定离开工作了17年的通用,前往亚马逊担任运营经理一职。眼看着博勒•戴维斯升迁,琼斯也信心大增,他说:“离开很不舍,但她的经历让我觉得这定是好机会。”(财富中文网)

本文另一版本刊登于《财富》杂志2020年11月刊,标题为《亚马逊的王牌工程师》。

译者:冯丰

审校:夏林

即使在正常情况下,亚马逊的全球分销网络也是地球上最复杂的物流系统之一。系统当中无数的地址、人名,还有各种技术,仿佛是在共跳一支极其复杂的舞蹈,结果是将数百万个快递送到正确的地方。

当新冠疫情来袭,常态顿成往事。然而在疫情封锁期,全美几乎所有人仍要工作、学习,而且只能在家购物。亚马逊订单突然激增,其中也包括大量囤积食品和卫生纸等,这导致运营网络一片混乱。而且,由于物流网络中多数员工没法在家工作(毕竟不可能在客厅里送快递或开叉车),突然之间亚马逊还要为数十万员工的安全负责,其中很多人面临感染新型冠状病毒的风险。

两大挑战都直接落在到亚马逊工作还不满一年的高管身上。艾丽西亚•博勒•戴维斯于2019年4月加入亚马逊,担任全球物流副总裁。从职位就能看出,博勒•戴维斯掌管着庞大的基础设施,目标是帮助消费者在亚马逊轻松购物。“物流业务是亚马逊零售业务的心脏,”追踪亚马逊的Baird Equity Research分析师科林•塞巴斯蒂安表示。由此博勒•戴维斯也变成行业领跑者,她管理着亚马逊全球数百座仓库,监督员工、物流和流程,以及理货机器人等多项技术。客户服务也囊括在内,疫情之中亚马逊的客户需要的服务比以往更多。

虽然博勒•戴维斯加入亚马逊不久,但她并不是新手。她在来到西雅图加入亚马逊之前曾于通用汽车工作25年且业绩顶尖,曾负责管理工厂,与工会谈判,监督开发热门新车型,还帮助公司挺过了艰难的召回事件。“在亚马逊,人们行动非常积极,”博勒•戴维斯说。“一旦发现问题,就要迅速找到解决方案并尝试不同的想法。如果找到了可行方案,就尽快分享推广。”疫情期间挑战不断升级时,博勒•戴维斯在通用汽车期间练就的强大多样的技能让她临危不惧。

首先要解决的问题是供应链不堪重负。疫情期间,亚马逊优先配送卫生用品、防护装备和其他疫情相关需求,非必需品发货则可能推迟数周。与此同时,庞大的新增需求量造成了瓶颈,要求配送渠道迅速拓展。博勒•戴维斯带动公司加速扩张,过去几年里,亚马逊在全球各地的物流中心面积每年增加约15%,仅2020年就将增长50%。过去6个月亚马逊雇佣的20万名员工中,大部分都是直接为新物流中心配备,而能如此迅速招聘20万人本身就很惊人。

更艰巨的任务则是保护员工安全。在博勒•戴维斯看来,保障安全意味着在仓库中增加社交距离规则且测量体温(刚开始用手持设备,后来用体温监测摄像头),增加新冠病毒筛查,并全面检查150个工作流程。就连指导员工配货的亚马逊物流算法也要改写,以实现人员密集度降低。口罩和消毒用品等关键产品持续短缺,亚马逊不得不寻找新供应商。“这可能是我做过最具挑战性的事,”博勒•戴维斯说。

亚马逊在安全方面并不完美,尤其是疫情初期。仓库一些员工抱怨说没机会享受带薪病假。纽约员工还发起了一场GoFundMe运动,支持同事无薪休假。如果有员工检测出阳性,一些仓库就得关闭。不过,博勒•戴维斯和其他高管充分了解疫情范围后,亚马逊开始疯狂投入——仅二季度就投入40亿美元改进工作流程并升级安全措施。

320000000

截至2020年10月,亚马逊全球物流设施的占地总面积达320000000平方英尺(数据来源:供应链咨询公司MWPVL国际)

本月早些时候亚马逊报告称,140万一线员工中近2万人自3月初以来检测呈阳性,其中包括Whole Foods超市员工、临时工和季节性员工。尽管数字听起来很高,但感染率仅为1.4%。而且亚马逊表示,根据所在社区的感染率计算,阳性病例总数比预期的少42%。

亚马逊的大力投入也收获了很突出的财务回报。二季度公司营收较去年同期飙升40%,达到创纪录的889亿美元。背后推手主要是新一波电商浪潮,目前电商业务占总销售额的近60%。在混乱的二季度里,亚马逊利润翻了一番达到创纪录的52亿美元。其业务弹性也让投资者放心,股票市值推高至1.6万亿美元。

抗疫胜利很可能也推动博勒•戴维斯的职位水涨船高。今年8月,她升任亚马逊高管核心团队S-team(S代表“高级”)成员,直接向首席执行官兼创始人杰夫•贝佐斯提供建议的重量级人物。现年50岁的博勒•戴维斯是第一位黑人,也是公司成立以来第四位跻身核心团队的女性。分析师认为,明年5月全球消费业务首席执行官,也是长期以来贝索斯的左膀右臂杰夫•威尔克将退休,届时高层人事将出现调整,她可能有进一步升迁机会。

博勒•戴维斯在通用汽车已证明自己可以胜任高层(她曾担任首席执行官玛丽•博拉的高级副总裁五年),也擅长灵活处理问题,职业上照此路线晋升也非常合理。她帮助亚马逊解决了诸多与疫情并不直接相关的问题,包括混乱的劳资关系和竞争对手的挑战等,可能对亚马逊维持市场主导地位很重要。虽然亚马逊不允许现任同事谈论博勒•戴维斯,但采访通用汽车前同事后,还是能侧面了解她从事当前职务拥有的优势。

博勒•戴维斯在底特律长大。母亲是记账员,父亲先在福特工厂工作,30多岁时上大学,毕业后在IBM当销售。(父母离婚后,她跟母亲住在一起,但父母都很关心她的生活和教育。)她小时候生活拮据,还记得9岁或10岁时试着修理房间里的东西。从老旧烘干机后面取出玩具并不困难,拼接熔化的铁线则麻烦一点。她回忆说:“那会可没法上谷歌搜索该怎么做,我被电过好几次。”

高中期间,这个热爱弄清楚各种东西运作原理的孩子参加了通用汽车赞助的暑期工程课程,也由此激发出她更宏大的抱负。博勒•戴维斯从西北大学化学工程专业毕业后,1994年加入通用汽车,在庞大的底特律-哈姆特马克工厂从事制造工作。通用汽车前人力资源主管克里斯•泰勒回忆称,你很快就能发现“她没准有一天能晋升为高管”。2007年,她成为通用汽车第一位非裔女性工厂经理,负责管理德克萨斯州阿灵顿市制造凯迪拉克凯雷德的工厂。

她事业上的大突破则跟小型车有关。2010年,通用汽车聘请博勒•戴维斯监督新的超紧凑车型雪佛兰Sonic。她负责设计并制定生产计划。对这位年轻的经理来说,“要考虑各不相同又得密切配合的领域,方能推出伟大的产品,”她说。通用汽车前高管,现在巴西现代汽车工作的乔尔•索亚雷斯•多斯安霍斯回忆称,该项目需要与通用汽车在韩国的伙伴密切合作,而当时韩国是男性主导的文化。“艾丽西亚在不同文化和国家之间应对得当,”他回忆说。讨论时她充分尊重男性,但坚定推进自己的议程,而且经常得胜。

Sonic在2010年底巴黎车展上正式推出,各种配色非常鲜亮,还包括一款掀背版,销量迅速蹿升。后来Sonic还屡获小型车领域最佳质量和可靠性奖。今年,研究公司J.D.Power表示,在各车型中Sonic出现质量问题最少。然而为了向电动汽车转型,通用汽车很快将停产Sonic,但很长时间里该款车相当畅销。Sonic的成功也推动博勒•戴维斯2012年升任负责全球质量和美国客户体验的副总裁,向另一位迅速崛起的通用高管巴拉汇报工作,2014年巴拉出任首席执行官。

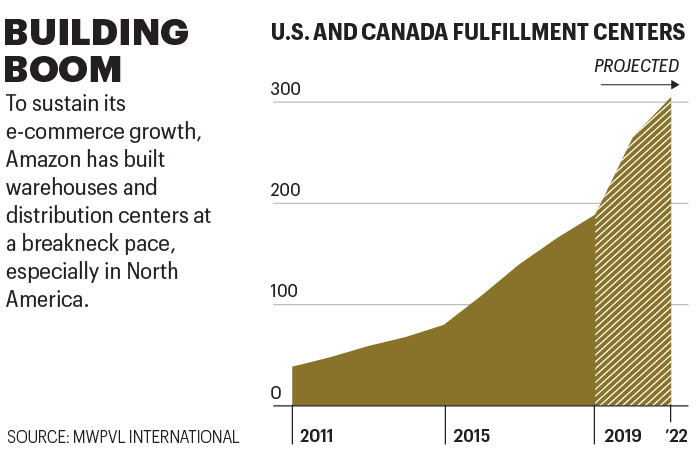

打造空间:为了维持电商业务增长,亚马逊以惊人的速度搭建了仓库和配送中心,尤其是在北美地区。数据来源:MWPVL国际

博勒•戴维斯全面负责质量期间,通用汽车的质量大幅改善。她表示,当时听取各级员工建议,寻找机会将一处工厂里的好方法在各处广泛应用。“如果经常跟高层交谈就会发现,说话时他们目光迷茫,然后继续说别的,”韦恩堡一家通用工厂的长期负责人乔纳森•琼斯回忆道,他曾与博勒•戴维斯多次会面。“她跟别人不一样,似乎很关心你说的话。”

她迅速反应的能力也曾帮助通用汽车应对危机。2014年初,通用汽车不得不召回近200万辆点火开关故障的车。客服电话量翻了一番,博勒•戴维斯迅速搭建了100名客服代表组成的特情小组,专门针对召回问题接受培训,随后成功将等待时间缩短到不到一分钟。

2016年,巴拉任命博勒•戴维斯接替退休传奇人物,从业37年的老将吉姆•德鲁卡,出任全球制造和劳资关系执行副总裁。该职位要负责监管31个国家的171家工厂,雇佣18万名工人。对博勒•戴维斯来说,回到制造业让她回忆起早期在通用汽车公司工作的时光,“我在工厂里经历了很多。基本上是在工厂里长大的,”她说,“绕了一圈回来,如今要负责全球制造业务,我感觉很谦卑。”

此次晋升也提升了她的公众形象,也让物流需求复杂程度堪比通用汽车的公司之一开始关注她。

杰夫•威尔克是毕业于普林斯顿大学的化学工程师,长期以来一直是杰夫•贝佐斯的得力助手,也是亚马逊庞大电商设备的设计师之一。几年前,通过一位共同的朋友牵线,威尔克认识了博勒•戴维斯,还一起吃了午饭。她回忆说,威尔克对公司庞大业务了解十分深入,让她印象深刻。他谈论起亚马逊如数家珍,就像她谈论通用汽车一样。

当时博尔•戴维斯除了在亚马逊购物之外,对公司本身了解不多。但她做了些研究之后,对亚马逊以客户为中心的文化相当认同。“这与我的价值观和我喜欢的工作方式产生了共鸣”,她说。威尔克对她同样印象深刻,后来发出了工作邀请。(“我了解也热爱汽车行业,但为何不去别的行业试试呢?”博勒•戴维斯现在说。)今年夏天威尔克发给员工宣布博勒•戴维斯升任核心团队的邮件中写道:“我们很快就达成了一致。她的领导经验、对技术的敏锐,尤其是热爱为一线工人奉献的精神让我深受触动。”

如今三项优势都在接受考验。疫情来袭之前,亚马逊就曾打算在美国更大范围内提供更多品类的商品一日达服务,有时因配送量增大而难以提速。分析师一致认为,如果要实现这一目标,仓库网络要更大也更高效,还要在靠近客服的地方设置更多配送点。截至2019年底,亚马逊在全球有约175个物流中心。“我们还要增加很多,”博勒•戴维斯告诉《财富》杂志。“可以说,我们很可能要建立250到300个中心,至少涉足16个国家。”

“我认为,随着亚马逊将更多送货和配送纳入自营范围,博勒•戴维斯的重要性只会进一步提升,”Baird分析师塞巴斯蒂安表示。

由于零售业务和盈利的云服务业务都在挣得大量现金,亚马逊的基础设施建设热潮并没有让投资者感到不安。今年亚马逊股价上涨了80%以上。随着谷歌、微软和其他竞争对手削减亚马逊在云计算领域的领先地位,未来其现金流可能会减弱。至少从理论上讲,反垄断威胁可能影响利润。但目前来看,博勒•戴维斯团队有足够资金满足客户的需要,相当令人羡慕。

100,000

亚马逊预计2020年最后三个月在美国和加拿大招聘新员工的人数

如何将员工安置在新仓库里可能更为棘手。而且接下来是传统上亚马逊业务最繁忙的假日购物季。最近博勒•戴维斯宣布,到今年年底公司在美国和加拿大还要再雇佣10万名员工。(不能全交给人类员工:随着博勒•戴维斯推出更多新物流中心,装配更多亚马逊新款理货机器人也很重要。)

迅速招聘优秀员工绝非易事,围绕亚马逊工作环境的争议也增加了难度。一些现任和前任员工称,除了对病假工资福利的投诉,亚马逊还因薪酬和工作流程受到批评,按照相关流程,算法强行规定员工活动,休息时间也受到严格监控。美国工人兄弟会和其他工会都试过将亚马逊员工组织起来,但迄今为止收效甚微。

博勒•戴维斯从事汽车行业期间,以跟普通员工关系良好闻名,如果她在亚马逊能坚持风格,对公司必定大有裨益。“在通用汽车,小时工在创意、改进和工作方式等方面做出了很大贡献,”她说, “有一点我肯定不会忘,那就是对沟通的期待。”

她非常了解身为某一空间里唯一的女性或者唯一的黑人是什么感觉,所以也希望帮助更多像她一样的人发展。“孤立无援可能很难。不管会不会成为肩头的负担,这都是现实,”她说。她提携了一些后辈,也在亚马逊员工亲和力小组会议上发言。“我觉得开端还不错,”她说。

她努力建立凝聚力的过程中,至少有一位热情员工的加入可以归功于她。韦恩堡工厂负责人乔纳森•琼斯最近决定离开工作了17年的通用,前往亚马逊担任运营经理一职。眼看着博勒•戴维斯升迁,琼斯也信心大增,他说:“离开很不舍,但她的经历让我觉得这定是好机会。”(财富中文网)

本文另一版本刊登于《财富》杂志2020年11月刊,标题为《亚马逊的王牌工程师》。

译者:冯丰

审校:夏林

Even under normal circumstances, Amazon’s global distribution network represents one of the planet’s most complicated logistics systems—an intricate dance of places, people, and technology whose choreography moves millions of packages a day.

When COVID-19 hit, normal went out the window. Pandemic lockdowns forced almost everyone in the U.S. to work, learn, and above all shop from home. A sudden surge of orders, including panic-buying of staples like bulk foods and toilet paper, brought chaos to Amazon’s operational web. And since most employees in that network couldn’t work from home (it’s hard to deliver a package or drive a forklift from your living room) the company suddenly became responsible for the safety of hundreds of thousands of essential workers—many of them at risk of exposure to the novel coronavirus.

Both of those challenges landed squarely on the desk of an executive who had been at Amazon for less than a year. Alicia Boler Davis joined Amazon in April 2019 as vice president of global customer fulfillment. As that sweeping title suggests, Boler Davis is in charge of much of the vast infrastructure that makes Amazon shopping feel effortless to consumers. “The fulfillment operations are the heartbeat of Amazon’s retail operations,” says Colin Sebastian, an analyst at Baird Equity Research who tracks the company. That would make Boler Davis the pacemaker: She runs the company’s hundreds of warehouses worldwide, overseeing employees, logistics, and processes, as well as technology that includes shelf-stocking robots. Customer service falls under Boler Davis’s umbrella, too—and in the pandemic, Amazon’s customers suddenly needed more service than ever before.

While Boler Davis was an Amazon newbie, she was anything but a rookie. She came to Seattle after 25 years as a top performer at General Motors—where she managed factories, negotiated with unions, oversaw the development of a new hit car model, and helped navigate the company through a perilous recall. “At Amazon, there’s a very high bias for action,” Boler Davis says. “Once you define a problem, you move very quickly to finding solutions and trying out different ideas. And then when you find something that works, you replicate that as quickly as possible.” The huge and varied toolkit that Boler Davis had developed at GM prepared her to do exactly that as COVID’s challenges escalated.

Among the first problems for her to solve was an overloaded supply chain. Amazon had to delay shipments for weeks on customer orders of nonessential items as it prioritized moving cleaning supplies, protective gear, and other pandemic-related needs. At the same time, the sheer volume of new demand created bottlenecks that demanded a speedy expansion of its distribution pipeline. Boler Davis took that expansion into overdrive: After increasing the square footage of its facilities worldwide by about 15% annually over the past few years, Amazon will grow it by 50% in 2020 alone. And most of the 200,000 workers Amazon has hired in the past six months—a staggering accomplishment in its own right—went straight in to staff those new facilities.

Far more daunting were the demands of keeping that staff safe. For Boler Davis, that meant adding social distancing rules in warehouses, conducting temperature checks (initially with handheld devices, later with thermal cameras), adding COVID-19 testing, and overhauling 150 different processes in all. Even Amazon’s logistics algorithms, which guide staff as they fill orders, had to be rewritten to account for less dense staffing. Critical items like masks and sanitizing supplies were continually running low, forcing Amazon to find new suppliers. “It was probably one of the most challenging things I’ve ever done,” says Boler Davis.

Amazon didn’t earn a perfect grade on safety, especially early on. Some warehouse employees complained that they couldn’t qualify for paid sick leave; New York City employees started a GoFundMe campaign to support fellow workers taking unpaid time off. A few warehouses had to close when workers tested positive. But when Boler Davis and other executives grasped the scope of the pandemic, Amazon started spending like mad—$4 billion in the second quarter alone—to revamp procedures and add safeguards.

320,000,000

TOTAL SQUARE FEET OF FLOOR SPACE IN AMAZON LOGISTICS FACILITIES WORLDWIDE AS OF OCT. 2020 (SOURCE: MWPVL INTERNATIONAL)

Earlier this month, Amazon reported that almost 20,000 of its 1.4 million frontline employees, a figure that includes Whole Foods staff, temps, and seasonal workers, had tested positive since the beginning of March. As high as that headline number sounded, it represented an infection rate of only 1.4%—and the company says that it added up to 42% fewer positive cases than would be expected based on infection rates in the communities where it operates.

Amazon’s overhaul paid off financially, as well. The company’s second-quarter revenue soared 40% from a year earlier, to a record $88.9 billion—driven primarily by the tidal wave of new e-commerce, which accounts for almost 60% of the company’s total sales. Its profits in that chaotic second quarter doubled to a record $5.2 billion. And Amazon’s resilience reassured investors, who have pushed its stock market value to $1.6 trillion.

The success against COVID likely boosted Boler Davis’s stock as well. This August she was named to Amazon’s S-team (the “S” stands for “senior”), the select inner circle that advises CEO and founder Jeff Bezos. Boler Davis, now 50, is the first Black person and only the fourth woman ever named to the S-team. Some analysts think she may rise further next year, in a reshuffling after the planned retirement of Jeff Wilke, CEO of consumer at Amazon and Bezos’s longtime No. 2.

It has been a fitting arc for someone who proved at GM that she could thrive as a senior leader (she served five years as a top lieutenant to CEO Mary Barra) and a nimble problem-solver. How Boler Davis helps Amazon navigate its non-pandemic problems—and there are plenty, including tumultuous labor relations and challenges from competitors—could help determine how long the company remains dominant. While Amazon declined to make current colleagues available to talk about Boler Davis, conversations with former GM colleagues offered a sense of how many strengths she brings to that role.

Boler Davis grew up in Detroit. Her mother was a bookkeeper, while her father worked in a Ford plant, then went to college in his thirties and became a salesman for IBM. (After her parents divorced, Boler Davis lived with her mother, but both of them stayed involved in her life and education.) There wasn’t much money to spare when she was young, and Boler Davis recalls trying to fix things around the house when she was 9 or 10 years old. Extricating a toy from the back of an old dryer wasn’t too tough; splicing the melted cord of an iron was trickier. Back then, “I couldn’t Google how to do those things,” she recalls. “I’ve gotten shocked a couple of times.”

A GM-sponsored summer engineering course during high school sparked bigger ambitions in a kid who liked to figure out how things worked. After graduating from Northwestern with a chemical engineering degree, Boler Davis joined GM in 1994, taking a manufacturing job at the massive Detroit-Hamtramck facility. She was spotted quickly as “someone we thought would be a senior executive someday,” recalls Chris Taylor, a former GM human resources leader. “She was one of my high-potential people.” By 2007 she had become GM’s first African-American female factory manager, overseeing the Arlington, Texas, plant that made Cadillac Escalades.

Her next big break involved a much smaller car. In 2010, GM tapped Boler Davis to oversee a new subcompact model, the Chevrolet Sonic. She was in charge of engineering the car as well as coming up with a plan for manufacturing it. For the young manager, the assignment meant “looking at the different areas that have to work together in order to deliver a great product,” she says. “That was fun.” The project required working closely with GM’s partners in South Korea, at the time a male-dominated culture, recalls Joel Soares dos Anjos, a former GM executive who now works for Hyundai in Brazil. “Alicia played very well between multiple cultures and countries,” he recalls. In arguments, she treated men respectfully but advanced her own agenda firmly, and often won.

Introduced at the Paris Motor Show late in 2010, the Sonic, which came in bright colors and included a hatchback version, quickly shot up sales charts. It went on to win frequent awards for best quality and reliability in the subcompact category. This year, research firm J.D. Power said the Sonic had the fewest quality issues of any model in any category. GM will soon discontinue the Sonic, as part of a broader shift toward electric vehicles, but it was a durable hit. It also helped Boler Davis land the job of vice president for global quality and U.S. customer experience in 2012—reporting to another fast-rising GM exec, Barra, who would become CEO in 2014.

During Boler Davis’s tenure as quality czar, GM substantially improved its record on that front. She says she sought to listen to employees at every level for suggestions, looking for opportunities to implement good ideas from one plant across the company’s operations. “When you talk with a lot of higher-ups, you know, their eyes wander, they’re moving on,” recalls Jonathan Jones, a longtime shift leader at a GM factory in Fort Wayne who has had many meetings with Boler Davis. “She was different. It always seemed like she cared what you had to say.”

Her knack for responsiveness also helped GM stem a major customer-relations crisis. In early 2014, the company had to recall almost 2 million vehicles that had faulty ignition switches. Customer service call volume doubled, but Boler Davis created a SWAT team of 100 reps who were specifically trained to handle recall questions, and they reduced wait times to under a minute.

Barra tapped Boler Davis in 2016 as executive vice president of global manufacturing and labor relations, where she would fill the shoes of a retiring legend, 37-year veteran Jim DeLuca. The role meant overseeing 171 factories in 31 countries, employing 180,000 workers. For Boler Davis, the return to manufacturing revived memories of her earliest days at GM. “I spent a lot of my career in the plant. You know, I grew up in the plant,” she says. “To be able to come full circle and have responsibility for global manufacturing was pretty humbling.”

The promotion also raised her public profile—and put her on the radar of one of the few companies whose logistics needs are as complicated and intricate as GM’s.

Jeff Wilke, a Princeton-trained chemical engineer, has long been Jeff Bezos’s right-hand man—and is one of the architects of Amazon’s enormous e-commerce apparatus. A few years back, a mutual friend introduced Wilke to Boler Davis, and they met for lunch. She recalls being impressed with Wilke’s depth of knowledge about his company’s vast operations; he could talk about Amazon the way she could talk about GM.

Boler Davis didn’t know much about Amazon at the time beyond having shopped there. But after she did some research, she was impressed by its customer-centric culture: It “resonated with my values and how I like to work,” she says. Wilke was equally impressed, and the meeting led to a job offer. (“I knew the automobile industry and loved it, but why not go and try something different?” Boler Davis now says.) In an email to employees this summer, announcing Boler Davis’s appointment to the S-team, Wilke wrote, “We hit it off right away. I was so impressed with her leadership experience, technical acumen, and especially her dedication to the workers on the shop floor.”

All three of those strengths are now being tested. Even before COVID hit, Amazon was aiming to offer one-day delivery in more of the country for a broader array of goods—and sometimes struggled to speed up delivery while handling greater volume. Its warehouse network, analysts agree, needs to be both bigger and more efficient, with more locations closer to customers. At the end of 2019, Amazon had about 175 fulfillment facilities worldwide. But “we’re adding a ton,” Boler Davis tells Fortune; today, “I’d say we probably have 250 to close to 300 across at least 16 countries.”

“I imagine [Boler Davis’s] role will only become more important to Amazon as they insource more transportation and delivery,” says Sebastian, the Baird analyst.

With both its retail operations and its profitable cloud services business throwing off cash, Amazon’s infrastructure spree hasn’t fazed investors. The stock is up more than 80% this year. As Google, Microsoft, and other competitors cut into Amazon’s cloud lead, the company’s cash flow could weaken in the future; antitrust threats could also, at least in theory, erode profits. But for now, Boler Davis’s team is in the enviable situation of having the money to build whatever they decide customers need.

100,000

NEW WORKERS AMAZON EXPECTS TO HIRE IN THE U.S. AND CANADA IN THE LAST THREE MONTHS OF 2020

Putting people in those new warehouses could be a trickier proposition. Just ahead is the holiday shopping season, traditionally Amazon’s busiest. Boler Davis announced recently that the company would need to hire another 100,000 workers by the end of this year just in the U.S. and Canada. (The humans won’t be working alone: Integrating more of Amazon’s new shelf-stocking robots is also a priority, as Boler Davis brings the new facilities online.)

Hiring good employees quickly is never easy, and it’s made more difficult at Amazon by controversy around working conditions. In addition to complaints about sick-pay benefits, the company has faced criticism over its wages and its workflow, in which algorithms dictate movements and breaks are tightly monitored, according to some current and former employees. The Teamsters and other unions have tried to organize Amazon’s workforce, though without much success so far.

Throughout her automotive career, Boler Davis had a reputation for building good relationships with the rank and file, and Amazon would certainly benefit if she could do the same there. At GM, “our hourly workforce contributed a lot to the ideas, to the improvements, to how things were done,” she says. “That’s something that I definitely bring with me: the expectation of engagement.”

As someone who knows what it’s like to be the only woman or the only Black person in a room, she also wants to bring people like her up through the company. “It can be hard being the only one. Whether you’re carrying it around on your shoulders or not, it’s the reality,” she says. She already has some protégés and has spoken at Amazon employee affinity group meetings. “I think I’m off to a good start,” she says.

As she strives to build cohesion, there’s at least one enthusiastic hire Boler Davis can claim credit for. Jonathan Jones, the factory shift leader from Fort Wayne, recently decided to leave GM after 17 years—for a job as an Amazon operations manager. Watching Boler Davis’s ascent gave him confidence, Jones says: “It’s hard to leave, but she made me feel like this is a good call.”

A version of this article appears in the November 2020 issue of Fortune with the headline, "Amazon's ace engineer."